With a wood supply barely matching current demand, there is explosive potential for wood processors. There's never been a better time for an update for their cutting tool manufacturers.

What is the difference between today and 20 years ago? Wood cutting materials, manufacturing conditions and worker skills have improved greatly. In a more sustainable business model, a carpentry tool manufacturer would have all the technology needed to design tools, program grinders, simulate prototypes and produce cutting tools without compromise. The good news is that you can now own this technology.

Tools for new materials in record time Wood and wood-like materials now use more exotic and new composites. Carpenters are exploring alternative materials, implementing new high performance laminates and using new finishes and finishes. These new materials require immediate cutting, meaning they can go from tooling concept to production in less time. However, the work of these new materials is often a frontier area. Cutlery manufacturers need to apply abstract and innovative thinking to any challenge and do so in record time.

The only way to be this responsive within 24 hours of a customer request is to create the design, test the delivery capability and give the customer a preview of what they will receive. How does it advance? Sometimes this process has to happen without touching the grinder.

Tool makers need to use their ingenuity with software. Programmable CNC machines developed by leading grinding experts and proprietary software empower toolmakers to work risk-free to meet customer goals.

Custom tools with complex geometries, tolerances, cut quality, which account for a larger percentage of overall shop output, require complex tool surface geometries, tight tolerances and cleaner cuts. Achieving more aggressive design features in tools for making parts with new materials such as wood is one of the biggest challenges for carpentry tool manufacturers. This tool requires a solution to control excessive heat transfer and optimize chip evacuation to prevent clogging. The software allows the G-code to be manually selected to more precisely direct the movement of the grinder (not just from the center, but from different entry points as needed) without wasting hours of guesswork and expensive materials.

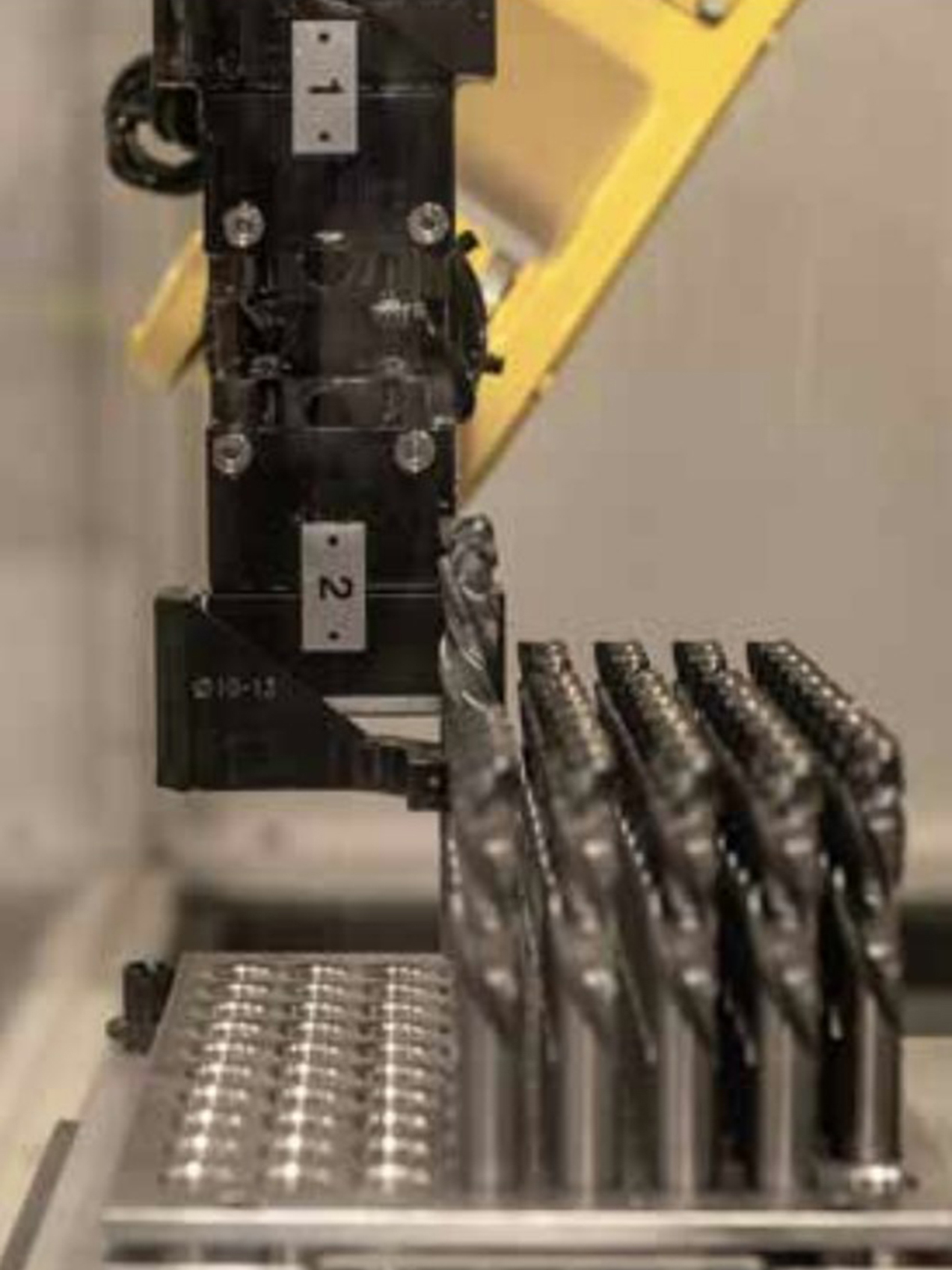

It combines advanced hardware and software for programming and motion feeds with the ability to create highly complex geometries at the push of a button. It can grind carbide from discs or damage PCD or other super hard materials to create unique tools from scratch. Modern and sophisticated grinding machines may offer an integrated wheel changer and automatic changer unit. Machines can be programmed to start the milling process closer to the part and use process holes, further reducing cycle times to increase productivity. In the case of PCD edge and point machining, milling and milling functions can be combined in the same machine.

Thus, a good tool can be up and running in 15 minutes and turn into a realistic scenario in an hour. The market also offers automation solutions that can be integrated with gantry robots, palletized part loaders that can process up to 1,500 components at a time and vision inspection systems. The potential exists today to take cutting tool production to unprecedented levels.

Closing the skills gap. Which brings us to the available workforce. The US Bureau of Labor Statistics says 29,000 new drivers will be needed by 2024 to meet the needs of retiring workers. A continued decline in the number of workers trained to cut tools will be a problem unless advances in manufacturing automation are stimulated. According to the McKinsey Global Institute, nearly nine out of ten hours that workers spend on manufacturing tasks could be shifted to automation.

New levels of productivity and growth can be achieved through automation, especially as machine tool OEMs offer standard automation deployment options for woodworking toolmakers with functionality and flexibility, such as: B. Tool replacement and machine maintenance.

Software resources like Tool Studio enable today's workers to reach their full potential. For example, a worker with no knowledge of the G-code CNC programming language can adapt to a simple operator interface with pre-programmed feeds and speeds. At the other end of the spectrum, trade school graduates with a general understanding of CAD/CAM can progress and quickly become proficient with Tool Studio applications to design and program CNC milling processes.

Success Story Leuco's Justin Harris was not yet 20 years old when he picked up cleaning and cooking equipment from Leuco's service department. Dreaming of becoming a machinist, he graduated from West Georgia Technical College with a degree in CAD/CAM applications for machine tools.

During this time, Harris began working as a machinist on Walter's manual and CNC machines. He then joined Leuco's engineering department and after four years held a management position in the carbide division.

Although Leuco outsourced all manufacturing at the time, Harris's technical skills and passion for innovation led Leuco president Jens Schulz to envision Walter developing carbide spirals for milling. This was the birth of the Leuco Spiral program, which is now sold worldwide. Today, decades later, Harris oversees nearly every manufacturing department at the Leuco corporate headquarters, where he and his team create complex and innovative tools for the wood industry and beyond.

Leverage Strategies and Experiences Do the challenges above describe your situation? Have you ever wondered how you can reduce your cost per part, shorten cycle times, and expand your knowledge to match what's happening around you? Today's problems can translate into tomorrow's competitive advantage for woodworking manufacturers.

Today's wood processors must push their limits, then go further to better serve forward-looking customers and prepare for future industry developments.

Source: United Grinding North America provides the professional training required, from the basic skill level to the most advanced skill level, in one facility. Courses range from general milling, operations and programming to individual training. This service can be provided on your machine at the manufacturing facility or at United Grinding's North American headquarters in Miamisburg, Ohio.

United Grinding's Automation Solutions, based in the United States, provides standard and custom tooling solutions for the company's eight grinder brands, as well as training to optimize tool and mill performance. For more information visit griding.com or email info@grinding.com.