Kent, Ohio. Since 2014, the Manufacturing Technology Program at Theodore Roosevelt High School, Kent, Ohio, has trained hundreds of aspiring CNC programmers, machines, and engineers for successful jobs in manufacturing. Troy Speer, an instructor in CAD and engineering technology, modern cabinetmaking, and basic wood and metal fabrication at Theodore Roosevelt High School, also known as Kent Roosevelt High School, has been involved in the program's career for the past 13 years. 24 years of study. . . Just as technology and industry have changed over the decades, so have Spear's teaching responsibilities.

“I grew up in this position,” he said. "I started teaching basic carpentry lessons and then introduced them into the 21st century."

In 2009, with the support of his then supervisor and former assistant, Speer asked the district to invest in a CNC milling machine. The application was accepted and the investment continued to pay off. Over the next several years, under the direction of a teacher, students produced everything from fully stocked kitchens intended for community members to regional computer cabinets, high chairs, and neighborhood preschool furniture.

The Kent Roosevelt program, which focuses on architectural carpentry, casting and cabinet making, is the only one of its kind in Ohio. Unfortunately, due to budget constraints, the Ohio Department of Education canceled this program. Although the industry-backed CTE woodworking program closed in 2013, Spear quickly learned a lesson.

“Completing the carpentry program helped me transition into manufacturing training,” he says. “What I do now is the result of the manufacture of wood products. Now it is all production - more than I did before.

The Kent Roosevelt Advanced Manufacturing Technology Program was launched in 2014, and includes primary and secondary school students from five other local school districts as well as Kent County. In the Computer Design and Engineering program, students use software and hardware to create working drawings, 3D solid models, parts, and assemblies. Laser engraving machines, 3D printers, hand tools, and CNC machines enable them to produce parts from metal, wood, and plastic.

Junior was first introduced to production by studying measurement and metrology. Armed with a micrometer and a steel ruler, they learn the measurement system and decimal equations that go along with fractional lessons. Building on these core skills, students perform transferable skills in a practical curriculum.

“A graduate student may attend a public Ohio institution for graduate or post-secondary studies and take three-credit unit courses that qualify for computer-assisted courses,” Speer said. "There is a second cycle that covers manufacturing operations."

From machine tooling basics to CAD/CAM

Early in the program, Speer focused on measurement and drawing, combining these disciplines to help young people understand how to calculate decimal equations and transfer that knowledge to machine tools or CNC systems. Although CNC technology is the main focus of the manufacturing program at Kent Roosevelt, students should be familiar with the basics of manufacturing.

“Many local employers say they hired adults from CNC schools and don't understand the relationship between decimals and movement,” Speer says. “All of our industry partners are asking us to teach manual processing, even if they use CNC more than anything else. Everyone still has some sort of manual processing for every component.

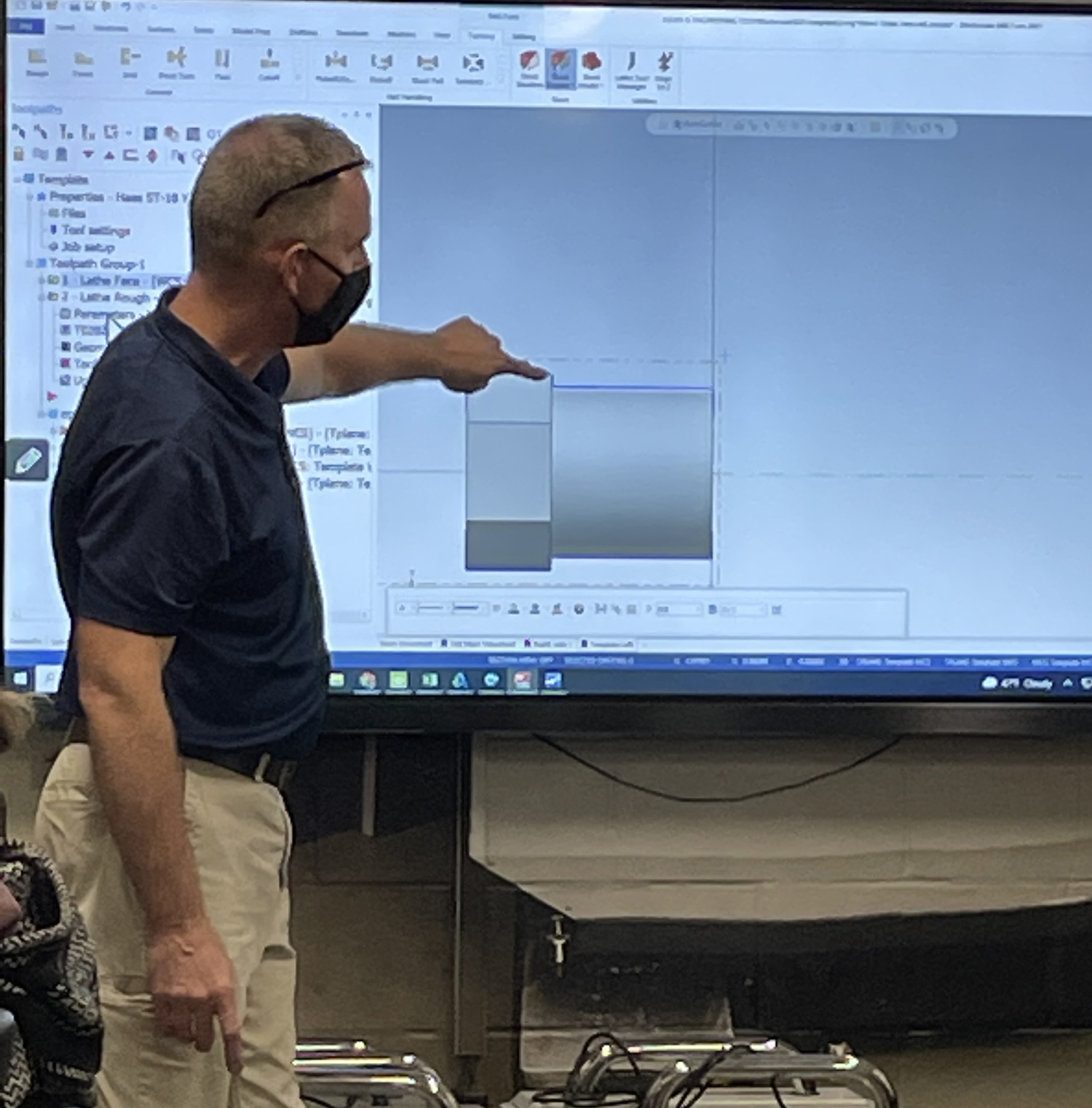

After the basics of manual manufacturing, Spear provides an introduction to CNC, demonstrates the controls and helps students become familiar with them. They learn how to set up machines, load parts, display seats, and operate automation programs. This is where Mastercam CAD/CAM software (CNC Software, LLC) comes to the rescue.

Through a series of lessons, students work on drawings, starting with 2D drawings created in a CAD program. They move to 3D drawing and begin to develop their visualization skills. Then they learn 3D solid modeling and Solidworks.

“At this point, students can appreciate the power of Mastercam and all of its features,” Speer said. “They can take this 3D solid model, draw tool paths, create some G-codes, bring it to our lab, load the material into the vise, and set up the tool. They load G-codes made in CAD/CAM. Through this process, they know, understand and are able to translate the code While it is running on the device, create its parts.

Kent Roosevelt manual lathes include the Clausing 13-inch engine lathe and the Bridgeport manual lathe. The manufacturing center also has band saws; CNC mill from Haas TM1; Haas TL1 lathe; Haas ST10 swivel center; Water gun Wardjet Lincoln Electric Reelold Simulator; and the Omnitech Selectx Pal CNC Milling Machine.

"From the beginning, we've always stuck with industrial tools, not educational versions," Speer said. "It doesn't mean that there is anything wrong with this type of machine, but our goal is to introduce students to industrial equipment and learn how to use it."

Next to the mechanic and carpentry workshop there is a computer lab with 18 computers and a training station equipped with the Mastercam program. Here students discover a strong and interesting relationship between software, design, programming, and processing. To create a prototype for their project, students have access to 10 3D printers from different manufacturers.

“The first step is to try to connect them and show that the program is going to be very linear and systematic,” Speer said. “Then we walked to the tree—we got something. Then we went back and worked on Mastercam.

Dynamic Motion Technology

Speer teaches wireframes, drawing, and engineering. Last year, the class worked on a device made of 2" x 3" aluminum blocks. The clip has a round pocket hexagon shape with holes drilled into each corner of the hexagon and two triangle pockets. Each drilled hole is tapped with 1/4"-20 spouts. Students use many different tools to create user interface elements. They draw sections in Wireframe and Solidworks modes, then import those sections into Mastercam and create tool paths. The students' drawings in Solidworks were used to 3D print the parts.

"This class was introduced to dynamic motion technology - especially dynamic milling - with this little hex side," says Speer. “I would like to thank Mastercam vendor, FASTech Inc. I cannot thank you enough for the help we received. Kevin Richardson, Scott Hardy, Josh Chubb and the rest of the team did a great job.

"The dynamic movement is really fun to introduce to students because we don't cut a lot of material. What we cut is removed quickly and easily.

After completing a widget project, each student has an aluminum version of the printed part, a wireframe version they designed and programmed, and a 3D steel model. Developing the same piece in multiple ways demonstrates the versatility and creativity of craftsmanship.

Once students understand the basics of design, programming, and automation, Spear is sure to stress the importance of machine simulation, which describes the cutting process on a virtual copy of the machine. . This ensures a safe and accurate tool path is created and avoids impacting the machine even before the workpiece is cut.

“I really enjoy teaching students how to use Backplot and Verify so they can model or figure out how to cut a machine,” he said. “Thanks to FASTech, we have a machine environment where we can monitor the operation of the virtual ST10. We can open and close the door and watch the pattern as it rotates. The tower turns. You can see if there is an accident or if a downsizing is possible.”

android project

In addition to creating small parts like the tools mentioned above, several classes in Builder work together to design and process large projects, including life-size remote control robots. The project, called Project Droid, was inspired by popular science fiction movie characters and continues to be a hit with students.

Before the idea of building a robot appeared, students made a lightsaber. The handle is shaped like a custom flashlight; The sleeve printed on a 3D printer covers the handle. The project was so successful and exciting that the students decided to make their own version of the popular movie Robot. Powered by a rolling toy electric motor, the Droid is the product of four different classes that have been in operation for four years. The last working class on the robot was called R5-V7.

Freshman Speer draws and designs plywood parts in Solidworks, and learns how to assemble, position and cut them on a CNC router. By the end of the year, they assembled the robotic devices.

The following year, students watched Project Droid in action and were ready to participate. They paint and create leather using Wardgate's waterjet cut and aluminum foil, along with 3D-printed props. Students cut and solder the legs that hold the wheels and the car together.

Spear's assistant teacher, Jeff B., was working in graduation as a pin connecting the legs to the wooden legs. The Bee was able to bring dynamic grinding to this class because they chose to use thicker aluminum to wrap around the bottom of the robots' legs.

professional skills

While Kent Roosevelt High School teachers focus on classroom projects, teaching software, computers, and processing skills, other groups of people play a major role in preparing students for jobs. Advisory boards made up of local producers provide information on critical skills for the entry-level workforce. In addition to sharing their industry knowledge, the partners take Spears and his students on tours of their facilities and offer them future employment opportunities. In the spring, company representatives were invited to Kent Roosevelt High School to participate in mock interviews with younger students.

“I tell my students that behind every mock interview is a potential job,” Speer says. This past spring, we had an explosion of questions from people we'd never heard of in the industry. They said, “We heard you have a program. We need workers - who do you have? We wanted that today.”

During interviews, students can tell industry partners they might be interested in future work and ask interviewers to keep their resume. This experience provides networking opportunities and the possibility to find summer jobs and internships for graduates. Paid internships are combined with manufacturing and technology courses credits.

The design and computer engineering students at Theodore Roosevelt High School did well upon graduation. With a comprehensive school curriculum, they are well prepared for a career in manufacturing. One area that Speer and Bee wanted to add to the program was print design. Schools already have plastic injection molding machines, so the next logical step is to teach students how to use them. Given the high school's location, preparing future programmers and robots to work in the plastics industry is a smart and far-sighted plan.

"Our state's alley is a big alley of mold," Speer said of his school's proximity to Akron. “With our injection molding machines, we hope to introduce students to a method for making and designing molds. This is especially true of the dynamic motion technology that Mastercam is known for. This is one area we are looking into.”

Source: Master comb. Please visit mastercam.com for more information.